Mahsulot tavsifi

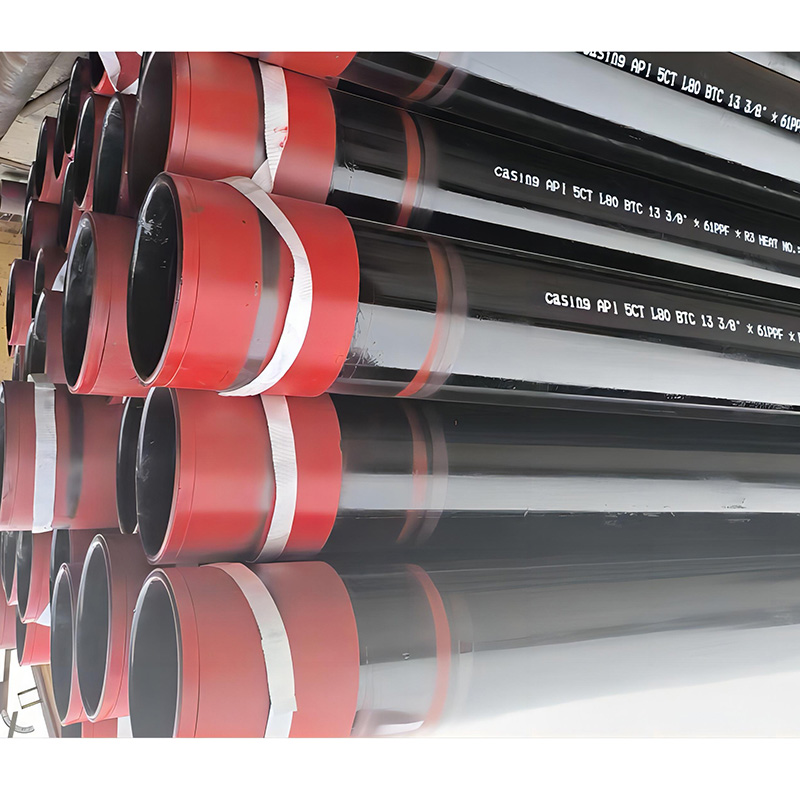

Neft va gaz qazib olishda keng qo'llaniladigan korpus va quvurlar. Korpus va quvurlar neft va gaz sanoatida uglevodorodlarni (neft va tabiiy gaz) yer osti suv omborlaridan yer yuzasiga qazib olish va tashish uchun ishlatiladigan muhim komponentlardir. Ular burg'ulash va ishlab chiqarish operatsiyalarining xavfsizligi, yaxlitligi va samaradorligini ta'minlashda muhim rol o'ynaydi.

Quvur - bu burg'ulash tugagandan so'ng xom neft va tabiiy gazni neft qatlamidan yoki gaz qatlamidan yerga o'tkazish uchun ishlatiladigan quvur turi. Quvurlash qazib olish jarayonida hosil bo'ladigan bosimni ta'minlashi mumkin. Quvurlash korpus bilan bir xil tarzda ishlab chiqariladi, ammo quvur trubasini qalinlashtirish uchun qo'shimcha ravishda "ko'tarish" deb ataladigan jarayon kerak.

Qoplama neft uchun yerga qazilgan quduqlarni himoya qilish uchun ishlatiladi. Burg'ulash quvuri singari ishlatiladigan neft quduqlari qoplama quvurlari ham eksenel kuchlanish bosimini ta'minlaydi, shuning uchun yuqori sifatli yuqori mustahkamlikdagi po'lat talab qilinadi. OCTG qoplamalari - bu quduqqa sementlangan katta diametrli quvurlar.

Texnik xususiyatlar

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: 1-guruh, 3-guruh, 4-guruh, 6-guruh, 7-guruh, 8-guruh, 9-guruh, 10-guruh, 11-guruh |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

ISO/API po'lat qoplamalar ro'yxati

| Yorliqlara | Tashqarida diametr D mm | Nominal chiziqli massab, c Shartlar va qoidalar kg/m3 | Devor qalinligi t mm | Yakuniy tugatish turi | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 1-toifa, Q | C90 T95 | P110 | 125-savol | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Jadval oxiridagi izohlarga qarang. | ||||||||||||

| Yorliqlara | Tashqarida diametr D mm | Nominal chiziqli massab, c Shartlar va qoidalar kg/m3 | Devor qalinligi t mm | Yakuniy tugatish turi | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 1-toifa, Q | C90 T95 | P110 | 125-savol | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19 685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Jadval oxiridagi izohlarga qarang. | ||||||||||||

| Yorliqlara | Tashqarida diametr D mm | Nominal chiziqli massab, c Shartlar va qoidalar kg/m3 | Devor qalinligi t mm | Yakuniy tugatish turi | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 1-toifa, Q | C90 T95 | P110 | 125-savol | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13 021 | 1105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Oddiy uchi, S = Kalta yumaloq ip, L = Uzun yumaloq ip, B = Tayanch ip, E = Ekstremal chiziq. | ||||||||||||

| ♦ Yorliqlar ma'lumot berish va buyurtma berishda yordam berish uchun mo'ljallangan. ♦ Nominal chiziqli massalar, tishli va bog'langan (2-ustun) faqat ma'lumot uchun ko'rsatilgan. ♦ Martensit xrom po'latlarining (L80 turlari 9Cr va 13Cr) zichligi uglerod po'latlaridan farq qiladi. Shuning uchun ko'rsatilgan massalar martensit xrom po'latlari uchun aniq emas. 0,989 massa tuzatish koeffitsientidan foydalanish mumkin. | ||||||||||||

| Yorliqlar | Tashqi diametr D mm | Oddiy chiziqli massa kg/m3 | Devor qalinligi t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

ISO/API po'lat quvurlari ro'yxati

| Yorliqlar | Tashqarida diametr D mm | Nominal chiziqli massalara, b | Devor qalin- ness t mm | Yakuniy tugatish turic | |||||||||||

| No- xafa Shartlar va qoidalar kg/m3 | Qo'shimcha xafa Shartlar va qoidalar kg/m3 | Butun bo'g'im kg/m3 | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Shartlar va qoidalar | EU Shartlar va qoidalar | IJ | H40 | J55 | L80 | N80 1-toifa, Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Oddiy uchi, N = Buzilmaydigan rezbali va ulangan, U = Tashqi buzilmaydigan rezbali va ulangan, I = Butun bo'g'in. | |||||||||||||||

| ♦ Nominal chiziqli massalar, iplar va muftalar (2, 3, 4-ustunlar) faqat ma'lumot uchun ko'rsatilgan. ♦ Martensit xrom po'latlarining (L80 turlari 9Cr va 13Cr) zichligi uglerod po'latlaridan farq qiladi. Shuning uchun ko'rsatilgan massalar martensit xrom po'latlari uchun aniq emas. 0,989 massa tuzatish koeffitsientidan foydalanish mumkin. ♦ Buzilmaydigan naychalar oddiy muftalar yoki maxsus qiyshiq muftalar bilan mavjud. Tashqi buzilmaydigan naychalar oddiy, maxsus qiyshiq yoki maxsus bo'shliq muftalari bilan mavjud. | |||||||||||||||

Standart va daraja

Qopqoq va quvurlar standart navlari:

API 5CT J55, K55, L80, N80, P110, C90, T95, H40

API 5CT korpus va quvur uchlari:

(STC) Qisqa yumaloq tishli korpus

(LC) Uzun yumaloq ipli korpus

(BC) Tayanch ipli korpus

(XC) Ekstremal chiziqli korpus

(NU) Buzilmaydigan naycha

(EU) Tashqi siqilish trubkasi

(IJ) Integral qo'shma naycha

Qopqoq va quvurlar yuqoridagi API5CT / API standartlari standartlariga muvofiq yetkazib berilishi kerak.

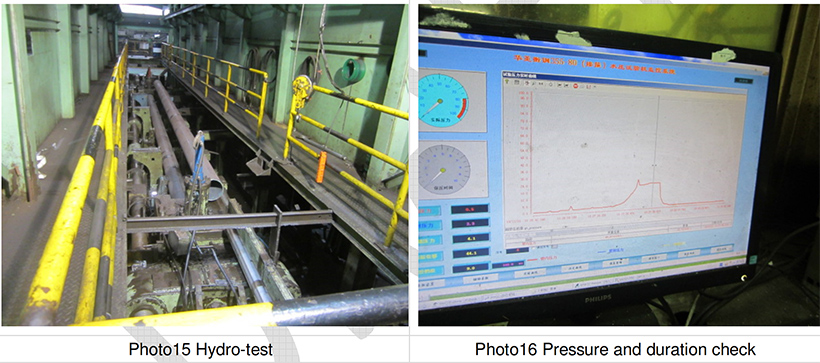

Sifat nazorati

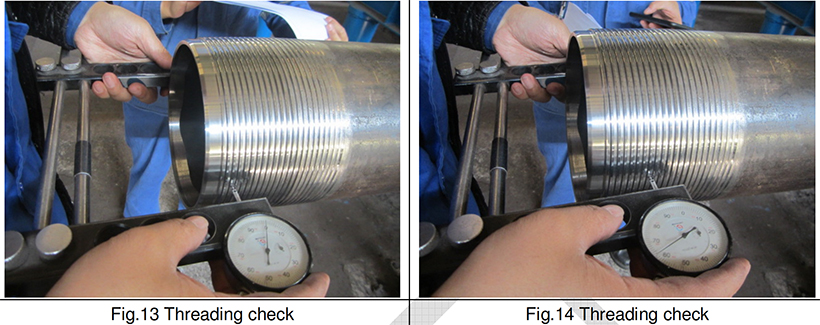

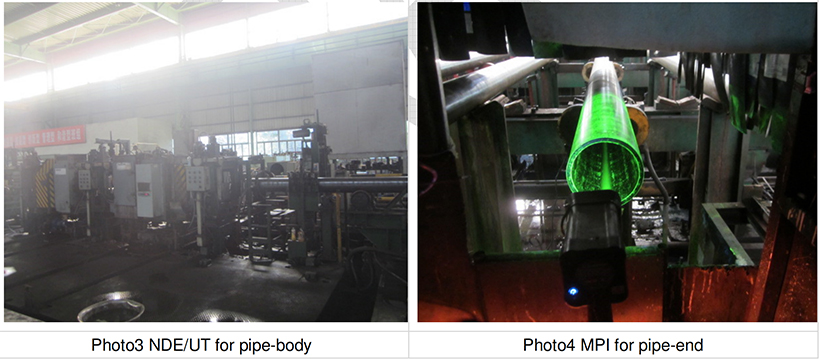

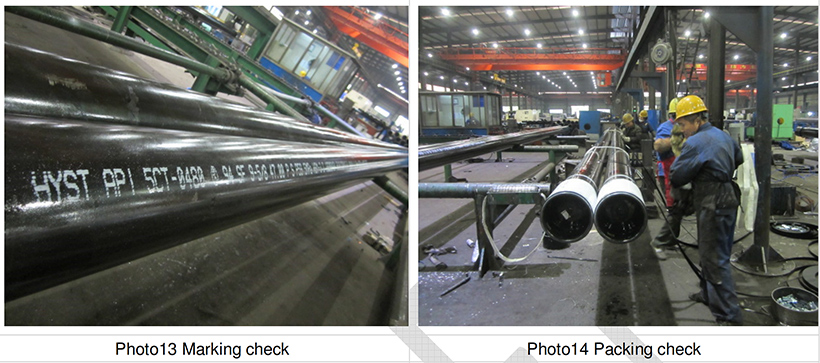

Xom ashyoni tekshirish, kimyoviy tahlil, mexanik sinov, vizual tekshirish, kuchlanish sinovi, o'lchamlarni tekshirish, egilish sinovi, tekislash sinovi, zarba sinovi, DWT sinovi, NDT sinovi, gidrostatik sinov, qattiqlik sinovi…..

Yetkazib berishdan oldin markalash, bo'yash.

Qadoqlash va yetkazib berish

Po'lat quvurlarni qadoqlash usuli tozalash, guruhlash, o'rash, bog'lash, mahkamlash, yorliqlash, palletlash (agar kerak bo'lsa), konteynerlash, saqlash, muhrlash, tashish va ochishni o'z ichiga oladi. Turli xil po'lat quvurlar va armaturalar turli xil qadoqlash usullariga ega. Ushbu keng qamrovli jarayon po'lat quvurlarning optimal holatda, mo'ljallangan foydalanishga tayyor holda yetkazib berilishini va belgilangan joyga yetib borishini ta'minlaydi.

Foydalanish va qo'llanilishi

Po'lat quvurlar zamonaviy sanoat va fuqarolik muhandisligining asosi bo'lib xizmat qiladi va butun dunyo bo'ylab jamiyatlar va iqtisodiyotlarning rivojlanishiga hissa qo'shadigan keng ko'lamli dasturlarni qo'llab-quvvatlaydi.

Biz ishlab chiqargan Womic Steel po'lat quvurlari va armaturalari neft, gaz, yoqilg'i va suv quvurlari, dengizda/quruqlikda, dengiz porti qurilishi loyihalari va qurilishi, chuqurlashtirish, konstruktiv po'lat, qoziqlar va ko'prik qurilishi loyihalari, shuningdek, konveyer roliklarini ishlab chiqarish uchun aniq po'lat quvurlar va boshqalar uchun keng qo'llaniladi...